DIGITECH CO., LTD. is the manufacture and sale manufacturer of various types of Torque testing machine, which specializes in the Torque measurement.

Multi Angle Torque TesterMODEL Tec-TQ5

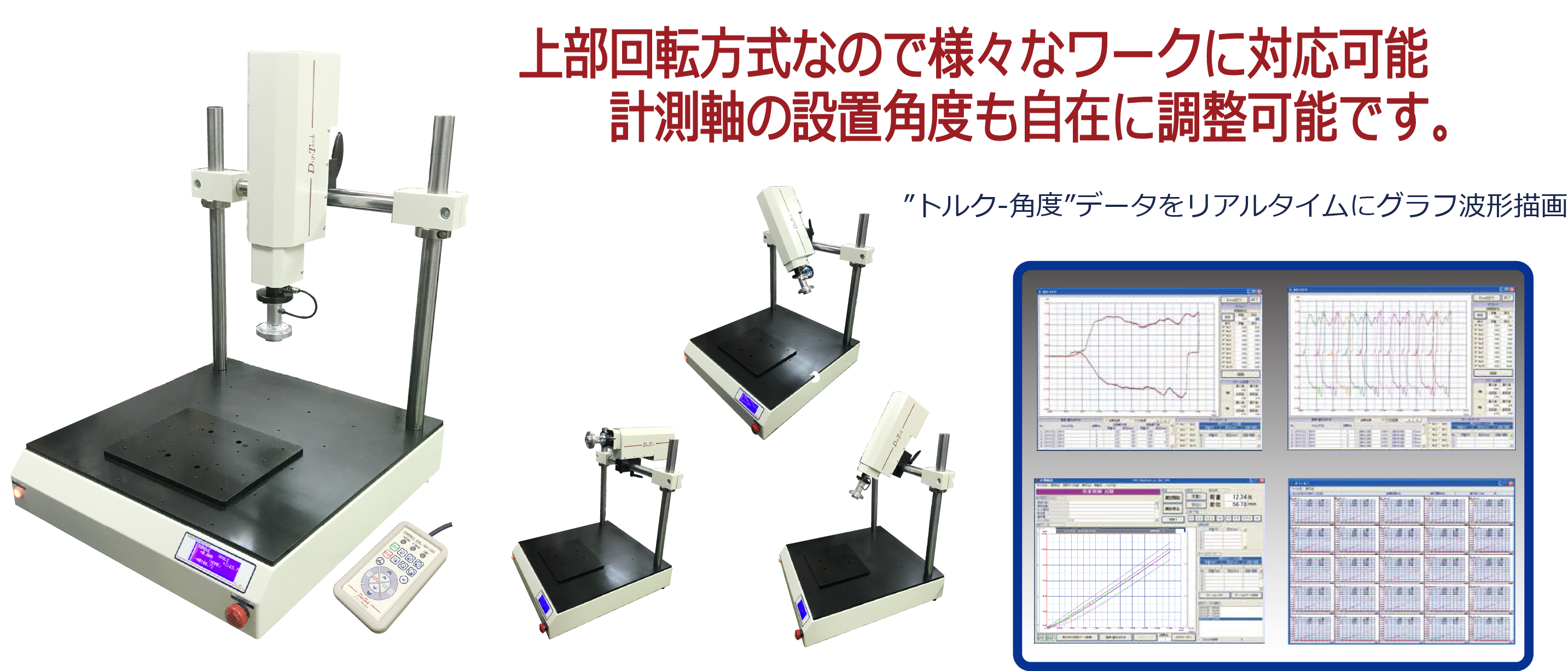

The direction of the measurement axis can be freely adjusted to match the angle of the specimen.

- The measuring unit can be freely adjusted in the height direction, left/right direction, left/right rotation, and front/rear rotation in a wide work space of 500mm x 500mm, so it is possible to match the mounting direction of the measuring unit to any workpiece.

- Detected test results are automatically saved and can be called up at any time for data analysis and report creation.

Tec-TQ5 Specification

| Specification / Mpodel | Tec-TQ5 |

| Capacity | 5N.m |

| Minimum torque display digits | Torque 4-digit or 5-digit display(By the torque cell) |

| Torque accuracy | Within ± 1% of indicated value |

| Angle resorution | 0.1 deg |

| Angle accuracy | within ±0.5° |

| Test speed | 1deg/min~1800deg/min |

| Maximum measurement angle | ±7200deg(±20 turn) |

| Number of torque cell channels | 3 channels |

| The maximum number of repetitions | 999999 times |

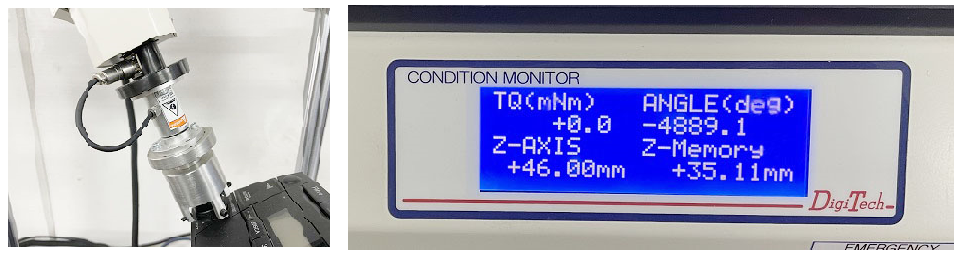

| Display Monitor | 128x64 dot Blue back light LCD |

| Z-axis movable distance | 80mm (with origin and measurement position memory function) |

| Protection circuit | Limit setting stop, overload stop, emergency stop SW |

| control method | Full PC control and remote control operation |

| Table size | W500×D500 |

| Communication method | USB2.0 |

| size | W506×H700×D536 |

| Weight | approx.42kg |

| Power source | AC100~240VV |

※Specifications are subject to change without notice.

CHARACTERISTIC.

- Equipped with an electric linear motion axis, it can be moved to the memory position with a single touch, so the test start position can be easily set when changing workpieces.

- High-precision torque measurement is possible by automatically correcting minute deflections of the torque cell and mechanical parts.

- The trigger function enables automatic angle zero reset at the moment of contact with the test object.

- The rotation axis can be inched by 0.1°, 1°, and 10°, making it easy to adjust the position.

- The automatic return function automatically returns to the test start position at the end of the test.

- Measured values can be displayed in real time as graphs and waveforms using the standard accessory PC software.

- The graph waveform overlay function makes it easy to compare waveforms in repeated tests.

- Graph waveform data can be developed on EXCEL in CSV format with one click.

- It is possible to create a test result/aggregation result report with a waveform with a one click.

- The AC100V to 240V compatible power input allows installation in any country or location.

- The software has a language switching function for Japanese, English, Korean, Traditional Chinese, and Simplified Chinese, so it can be installed at different production bases with confidence.

【Corresponding test an example】

- Rotating knob operating force test

- Bottle cap opening test

- Torsion test

- Rotational friction force test, etc.

It is also possible to perform a continuous repetition test and pick up data every arbitrary number of times.

【The main function of this software】

- Test conditions save number(Limitless(By HDD capacity))

- Test results save number(Limitless(By HDD capacity))

- Waveform data reading function of test results

- Real-time waveform comparison measurement by the superimposed waveform measurement function

- Speed adjustment function waveform reload function

- Macro formula registration function

- Area specified enlarged display function in the waveform data

- Cursor point data registration function of the waveform data(Up to 10 points)

- Graph back, grid lines, line color of graphic lines and the like, any setting function of the line type

- Side-by-side display function of waveform data(A4 sheet minimum 1 waveform-Up to 25 waveforms)

- Cascade function of waveform data(The maximum registration drawable number 10 data)

- Cursor point data registration function in Cascade during the display(Up to 10 points)

- Creating reports collectively by the export function to EXCEL

13-1. Export individual test results

13-2. Test results list・Aggregate result export

13-3. Waveform log data CSV format export

13-4. Tile export

13-5. Display export superposition

13-6. Macro expansion test results export - Clipboard copy function of the measurement screen

- 0.01mm、0.10mm、1.00mm,Step movement and continuous movement and stop

- Limit stop position setting function of the testing machine

- Language switching function(Japanese, English, Korean, Simplified Chinese, Traditional Chinese)

サイドメニュー

- Digital Force Gauge

Model-DTG series - Portable Torque Gauge

Model-DTR-200N / DTR-500N /

DTR-1000N - External Connection Force Gauge

Model-DTW-5N / DTW-20N /

DTW-2000N - Rod-type load cell connection type

Model-DTW-200N-DML / DTW-1000N-DML / DTW-2000N-DML - Digital Force Indicator

Model-SS100 - Automatic Test Stand

Model ASM-1000 - High load type Automatic Test Stand

Model AFS-2000 - Switch Feeling Gauge

Model DTF-10N / DTF-20N

- Automatic Multi Force Analyzer

Model-FT-501 - Automatic Switch Feeling Analyzer

Model-FT-502 - Automatic Multi Force Analyzer

Model-FWT - Long Stroke Force Analyzer

Model-VIT-2000 - Smart Force Analyzer

Model Tec-01 - Smart Switch Feeling Analyzer

Model Tec-01F - Automatic 3D Switch Feeling Analyzer

Model Tec-3D / Tec3DW

DIGITECH CO., LTD.

557-0063

1-6-2 MINAMITSUMORI. NISHINARI-KU. OSAKA. JAPAN

TEL:+81-06-6655-5200

FAX:+81-06-6655-5800