DIGITECH CO., LTD. is the manufacture and sale manufacturer of various types of load testing machine, which specializes in the load measurement.

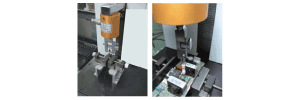

Automatic Multi Force AnalyzerMODEL FT-501

It corresponds to a multi-for a variety of user needs.

- Displacement control measurement and load control has three test mode function of (creep control) measurement and comparator control measurement, is a high-precision load test machine for a variety of user needs.

- The exact pressure test in 0.01mm unit, the amount of deformation of the measurement and the maximum value measurement by the pressure of the specified load, breaking value measurement, and automatic measurement with the waveform drawing, such as insertion force measurement.

- Detection and test results are automatically saved, at any time and any call you can create data analysis and reporting.

FT-501 Specification

| Specification / Mpodel | FT-501 |

| Capacity | Body maximum load1000N(100kgf)、Test load rating is due to the load cell |

| Minimum load display digits | Load 4-digit display(By the load cell) |

| Load accuracy | Within ± 0.5% of indicated value |

| Length resorution | 0.01mm(0.001mm option) |

| Displacement accuracy | ±20μm+0.0001L(mm) |

| Test speed | 0.1~600mm/min |

| Maximum measurement length | 230mm(Without load cell) |

| Measurement content | Displacement set load value detection, the detection load setting displacement, maximum breaking value, ON / OFF-point measurement |

| The maximum number of repetitions | 999999 times |

| The maximum measuring the number of data | 1000 data |

| Display Monitor | 8.4-inch TFT color LCD touch panel |

| External controller | Jog shuttle dial (7 stage variable speed control, inching control), the start of the test, stop |

| Protection circuit | Limit setting stop, overload stop, emergency stop SW |

| Built-in printer | Thermal paper type thermal dot printer |

| Table size | W480×D230 |

| Communication method | USB1.1 |

| size | W480×H635×D485 |

| Weight | approx.60kg |

| Power source | AC100 or 220V |

※Specifications are subject to change without notice.

CHARACTERISTIC.

- The smallest displacement setting unit is to 0.01mm for proper implementation ofthe pressure control to detect load data.

- Through load setting any pressure force is precisely controlled to detect the amount of deformation and displacement data of the test piece.

- The fine movement setting of load and displacement are available to perform broken or connector’s insertion test.

- Displaying bar graph or waveform of specification judgment can realize measurement data visually.

- Macro calculation formula arbitrarily capture, you can automatically calculate a variety of test results from the measured waveform data.。

- JOG Shuttle controller is applied for manual control, start and stop of the tester can be performed by hand.

- Also the language can be switched at different production sites in Japanese, English, Korean, Simplified Chinese, Traditional Chinese You can introduce immediately.

- Corresponding to the high-speed communication with a PC with a USB adoption. Software testing machine control and various data processing options are available.

【Corresponding test an example】

- Compression test

- Tensile test

- Break test

- Connector insertion and removal test

- Creep test

- Spring test

- Peel test

- 3-point bending test, etc.

Continuous repeat test is done, you can pick up the data to any number of times every.

【The main function of this software】

- Test conditions save number(Limitless(By HDD capacity))

- Test results save number(Limitless(By HDD capacity))

- Waveform data reading function of test results

- Real-time waveform comparison measurement by the superimposed waveform measurement function

- Speed adjustment function waveform reload function

- Macro formula registration function

- Area specified enlarged display function in the waveform data

- Cursor point data registration function of the waveform data(Up to 10 points)

- Graph back, grid lines, line color of graphic lines and the like, any setting function of the line type

- Side-by-side display function of waveform data(A4 sheet minimum 1 waveform-Up to 25 waveforms)

- Cascade function of waveform data(The maximum registration drawable number 10 data)

- Cursor point data registration function in Cascade during the display(Up to 10 points)

- Creating reports collectively by the export function to EXCEL

13-1. Export individual test results

13-2. Test results list・Aggregate result export

13-3. Waveform log data CSV format export

13-4. Tile export

13-5. Display export superposition

13-6. Macro expansion test results export - Clipboard copy function of the measurement screen

- 0.01mm、0.10mm、1.00mm,Step movement and continuous movement and stop

- Limit stop position setting function of the testing machine

- Language switching function(Japanese, English, Korean, Simplified Chinese, Traditional Chinese)

サイドメニュー

- Digital Force Gauge

Model-DTG series - Portable Torque Gauge

Model-DTR-200N / DTR-500N /

DTR-1000N - External Connection Force Gauge

Model-DTW-5N / DTW-20N /

DTW-2000N - Rod-type load cell connection type

Model-DTW-200N-DML / DTW-1000N-DML / DTW-2000N-DML - Digital Force Indicator

Model-SS100 - Automatic Test Stand

Model ASM-1000 - High load type Automatic Test Stand

Model AFS-2000 - Switch Feeling Gauge

Model DTF-10N / DTF-20N

- Automatic Multi Force Analyzer

Model-FT-501 - Automatic Switch Feeling Analyzer

Model-FT-502 - Automatic Multi Force Analyzer

Model-FWT - Long Stroke Force Analyzer

Model-VIT-2000 - Smart Force Analyzer

Model Tec-01 - Smart Switch Feeling Analyzer

Model Tec-01F - Automatic 3D Switch Feeling Analyzer

Model Tec-3D / Tec3DW

DIGITECH CO., LTD.

557-0063

1-6-2 MINAMITSUMORI. NISHINARI-KU. OSAKA. JAPAN

TEL:+81-06-6655-5200

FAX:+81-06-6655-5800